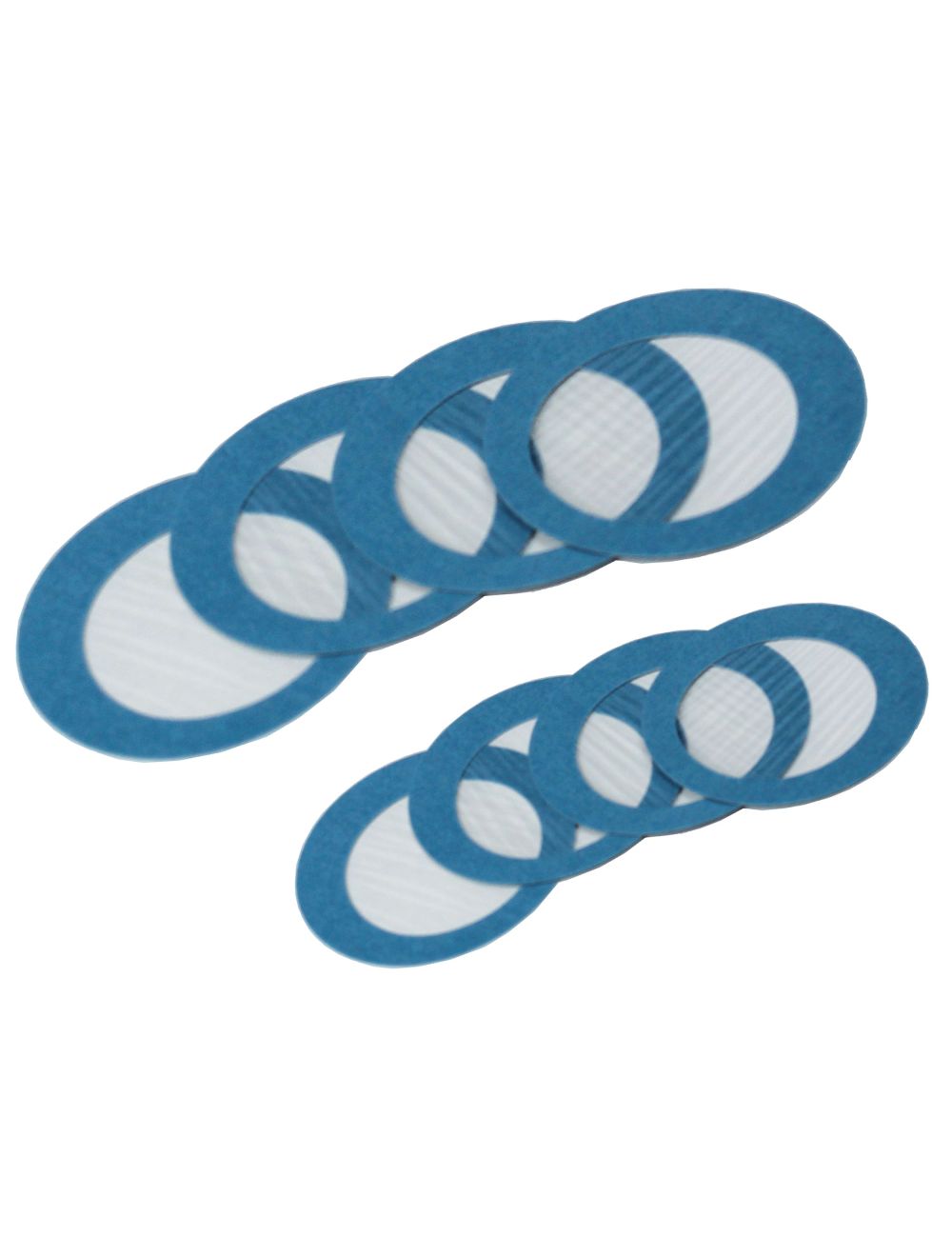

2042R6M3.6: SpectroFilm® Self-Sticking Safety XRF Secondary Film, 3.6 µm Mylar®,1.65" (42mm) Dia. 25/Pkg

SpectroFilm® offers the analyst a practical means to protect the x-ray tube and detector windows and related electronics from exposure to accidental sample material spillage.

Features

• Protects sensitive electronics from leakage

• Prevents damage to

• X-Ray tube windows

• X-Ray detector windows

• Sensitive Electronics

• Prevents costly cleanups

• Variety of sizes

• Custom sizes available

Package

• 25 sheets/package

Made in USA

SpectroFilm® offers the analyst a practical means to protect the x-ray tube and detector windows and related electronics from exposure to accidental sample material spillage. This is easily accomplished by affixing a self-sticking SpectroFilm® Safety Secondary Window between the stage separating the lower electronics compartment and upper sample chamber. A SpectroFilm® Self-Sticking Safety Secondary Window consists of a thin-film substance pre-affixed to a blue paper frame with a central aperture and an adhesive backing on the obverse side. Adhesive is protected with a removable release paper to expose the adhesive in readiness for attachment covering the opening in the platform intended to maintain separation between the sample holder and electronics chambers. Sample spillages are collected on the thin-film substance.

Thin-Film Materials Available

SpectroFilm® is available in several different thin-film substances that offer a broad range of chemical resistance to sample spillages: Mylar®, Prolene® and especially Etnom®, which is noted for its exceptional resistance to both aliphatic and aromatic hydrocarbons. SpectroFilm® Safety Film is available in three similar thin-film gauges of similar percent transmittance values and tensile sample retention strengths.

Easy-to-Use

Prepare the location where the SpectroFilm® is to be applied by cleaning and removing any residual oil or particles to provide a good bonding surface. Remove the release paper to expose the adhesive layer surface. Center the SpectroFilm® with the adhesive surface faced down directly over the aperture in the platform separating the sample holder and electronics compartments. Firmly press down the paper frame edges to ensure a complete and effective protective thin-film shield. Replace the SpectroFilm® Safety Secondary Film periodically to avoid the thin-film from becoming brittle after extended usage rendering it potentially ineffective. Thoroughly absorb, clean and dry any residual spillages and the surface separating the platform prior to re-applying a new SpectroFilm® Safety Film.

NOTE: For effective seals the platform must be thoroughly cleaned and free of any oily substances, residual particles and other materials that may impair adhesion of the SpectroFilm®.

For ease of identification, the obverse side of the SpectroFilm® is dark blue and the reverse side is lighter in color attributed to the translucence of the white release paper. SpectroFilm® is available with square or round paper frames of user choice. Removal of the release paper exposes the adhesive to secure the SpectroFilm® Safety Film in position.

Semi-Custom SpectroFilm®

SpectroFilm® can be made with virtually any thin-film material and thickness that is availale for the SpectroMembrane® product line. Additonally there are many other combination of sizes that can be made with our in-house equipment, for example a film with a 14mm aperture can be made with a 60mm diameter. Please contact us for your specific requirements.

Reg. US Patent No: 8,565,375

ETNOM® Etnom® was the first thin-film substance to chemically resist attack by aliphatic and especially aromatic hydrocarbons and have the unique characteristic of contracting when exposed to petrochemical hydrocarbons. This unique characteristic allows the thin film to remain taut when exposed to samples containing these hydrocarbons and maintain a consistent taut flat sample support window plane during the entire integration time of analysis. Etnom® is available in a variety of thicknesses ranging from 1.5 through 3.0µm; it is frequently used and ideally suitable for sulfur analysis in aliphatic and particularly aromatic hydrocarbons. 2.0, 2.5 and 3.0µm Etnom® thin-films are limited in availability only to SpectroMembrane® Carrier Frames. Prolene® Prolene® thin-film is a two constituent element combination of carbon and hydrogen. The light carbon and hydrogen element constituents together with gauge thickness translate into mass attenuation coefficients providing high % Transmittance values, an advantage for investigating the less energetic (KeV) analyte spectral lines in low element concentrations. Prolene® represents a good general purpose thin-film for most chemical solution samples except for those that consist of ethers or aromatic and halogenated hydrocarbons. It also is characterized with a relatively high sample retention tensile strength for safely containing samples in their sample cups. Prolene® thin-film is available in 3.0 and 4.0µm gauges and in SpectroMembrane® Carrier Frames. MYLAR® At one time, Mylar® thin-film was the only substance used in the XRF spectrochemical field and supplied only in roll form. With the passage of time, Chemplex® introduced the expansion of the Mylar® product line to include additional gauges and all other forms of physical presentation such as pre-cut square sheets, pre-cut circles, perforated pre-cut squares in rolls and recently in SpectroMembrane® Carrier Frames. Mylar® is a relatively good thin-film substance for general purpose aqueous sample solution containment. It is has an excellent sample retention tensile strength. It is not suitable for containing aliphatic alcohols, alkalies, esters, aromatic hydrocarbons and keytones.

® Prolene, SpectroFilm, Etnom and Chemplex are registered trademarks of Chemplex Industries, Inc; all rights reserved. ® Mylar is a registered trademark of E.I. DuPont de Nemours & Co. |

| No |